When you first start out in Motorsports, the essentials are still the same: better Brake Pads, stickier Tires and Seat Time.

For those of you who have had the pleasure of riding in one of my vehicles, you know that I have a reputation. It isn’t for how fast my cars are (because they aren’t) but I have a reputation for “dropping anchor.” I brake hard, and late, because I have confidence in my equipment. I only have such confidence because I have invested the time and research into upgrading my brakes. New brake pads alone aren’t the answer, as there are a few extras to consider when upgrading your brakes!

With us for Break/Fix episode #158 is Wendy Charlier, General Manager for Porterfield Brakes – an industry leader in performance brakes, joining us for a technical chat about “What’s Stopping You?”

In our discussion with Wendy, we cover topics like:

- Tell us about Porterfield – Who/When/Where — and explain the “brand name” and company history

- Talk about how brake systems, ABS, etc work in general. Plenty of folks out there that drive/race cars and have no idea how they work.

- Let’s explain braking terminology (scroll down for a comprehensive list)

- Importance of proper/better….

- Brake Fluid – explain dry/wet/boil temps

- Brake Lines

- Brake System (Calipers)

- Brake Rotors: Solid vs Slotted vs Drilled

- Brake Cooling Ducts – Fact or Fiction?

- Pad Compounds – How to pick the right brake pads?

- How to “check your brakes” for wear and also optimal performance

- and much, much more!

Porterfield Brakes services all kinds of performance applications related to your vehicle’s braking system, including brake pads, rotors, calipers, fluids, full brake kits as well as other performance & racing components, like suspensions, oil coolers, starters, heat protection items, and batteries, and much more. If you need any brake pads for virtually any car or truck, they have them or will make them for you. So be sure to check out Porterfield Brakes before making your next purchase. You can find Porterfield at www.porterfield-brakes.com or @porterfieldbrakes on instagram and facebook.

For more details on everything we talked about in this episode, head on over to the original “What’s Stopping You?” for an in-depth review of all the information in this episode.

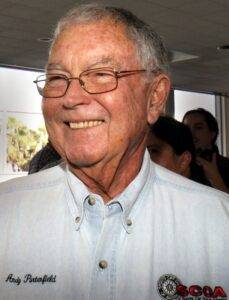

Andy Porterfield (1931-2012)

Andy Porterfield was born June 1, 1931. He lettered in track in high school in Los Angeles and earned a degree in business from Chico State. In addition to racing, he played racquetball and water skied and always kept himself in good shape. Until the mid-80s, he was a partner in a company that built parts for nuclear power plants. He said he saw the writing on the wall and managed to sell his share of the business before the bottom fell out of the nuclear power industry. During his time racing Corvettes, Andy learned that stopping was as important as going.

For a long time, Corvettes were sadly lacking in the stopping department. As a result he fitted some British Ferodo brake linings. One day at Riverside, the Ferodo rep asked him to take on the distributorship in the United States. He accepted and began the ongoing brake business that bore his name. Today Porterfield Enterprises manufactures its own brake pads, rotors and distributes for other companies. His pads and other brake parts are vital to the racing community. In addition, they make high performance street pads and supply brakes for U.S. Military aircraft.

He had a distinguished racing career. He won a national championship twice he and won 195 national races. He was the Southern Pacific Division Champion 23 times and the Regional Champion 19 times. Overall he won over 400 races. He enjoyed it and had fun. At the professional level, he ran Can-Am in the 60s with 4 podium finishes. He ran 40 Trans-Am events and 20 IMSA races. Trans-Am finished in the top ten 13 times. He spent time in a sprint car and a stock car. He raced every year since 1956 including 2012 – 56 years behind the wheel. In the 70s he got involved in club governance. He served on the Cal Club Board for 16 years, as RE 5 years and in 1985 was first elected to the National Board of Directors. The spec racer business, SCCA Enterprises, was going through a difficult time and an astute businessman was needed.

Andy was named Chairman of the Board of SCCA Enterprises and helped pull that business from defeat. Andy coordinated the worker effort at the Long Beach Grand Prix every year. In 2008 he received the McGill award and in 2009 the Woolf Barnato Award. Andy Porterfield made significant contributions to motorsports. He volunteered more time and effort than most. He was conscientious and an astute businessman, faithful to the Club to the very end. His passion for this club is unequaled.

SOURCE: SCCA.COM

Braking Terminology

Brake Fade: “The reduction in stopping power that can occur after repeated or sustained application of the brakes, especially in high load or high speed conditions.” (Source: Wikipedia); Brake Fade is a result of the pad material exceeding its heat threshold and becoming ineffective. Taking a cool down lap or two simulating street driving will allow the pads to cool down enough to be used again. Note that once a pad has suffered from Brake Fade it’s very easy for the compound to begin to deteriorate or, even worse, “glaze” (Note: a glazed pad has been overheated and cooled quickly and becomes shiny and unable to grab the rotor effectively. Glazing is an extreme case, but the end result is much like that of pottery in a kiln).

Warped Rotors: The most common sign of a warped brake rotor is vibration through the brake pedal when pressure is applied on them and can also be felt in the steering wheel. Sometimes you can feel it even when there is only a light amount of pedal pressure on the brakes. Other times, it can only be felt when slowing down drastically from higher speeds. However, a “warped rotor” is a bit of misnomer, as a majority of the time this sensation is a result of brake pad material transfer and build-up on the rotor. Swapping back and forth between pad compounds on the same rotors is a major cause of this issue. Try and “re-bed” your pads to clear the build-up. You might have to take the pads off and rough them up, before re-bedding as well.

Bedding Pads: Tire Rack’s article on proper Bedding of Pads, covers various types of pads and the bedding procedures. Commit these to memory for your pad type.

Uneven Pad Wear: Many cars suffer from uneven pad wear. Two primary causes of uneven wear result from single piston calipers (aka “side pull brake”) where the inner pad — which is doing all the work — will be thinner than the outer pad. This is a natural occurrence for this type of brake caliper. If the pads are not side specific (“directional”), we recommend flipping them from inside-to-outside to get more life out of the pads. The other common occurrence of uneven pad wear comes from larger 4 and 6 piston calipers (Brembo, Porsche, etc), where the “leading edge” of the pad will wear out quicker than the trailing edge. This is a result of how the fluid moves through the caliper and actuates the pistons. There is no way to fix this, so you must be diligent in rotating your pads to get even wear out of them. Generally, these types of braking systems make it easy to flip/rotate the pads between sessions, days, or events.

Boil-back: Boil-back is one of the causes of brake fade. Improper or old brake fluid can overheat, causing it to boil/burn and resulting in a mushy pedal. The pad grip will be consistent but the pedal feel is terrible. Often seen when the proper steps haven’t been taken to upgrade the fluids for track-only pads.

Knock-back: Knock-back is an uncommon situation in which the fluid/piston/pad will retract from the rotor creating a dead zone before the pads are able to grab effectively again. The folks over at Stop-Tech have a great write-up on this condition. Mastering a technique like left-foot braking will aide you if your vehicle is prone to knock-back.

ABS: Without getting into a long debate about the merits and problems of ABS at the track, know that even though you might not feel the ABS working on-track, it’s still active. ABS adds more heat and pressure on the fluid and pads. Learning techniques like threshold braking (although difficult to master) will help in Pad/Fluid longevity for all vehicles.

Traction Control & Stability Management: As much as Traction and Stability Management (“The Nannies”) can keep even unruly vehicles manageable, it wreaks havoc on the braking system. A majority of the TCS systems leverage the ABS to stabilize the vehicle. This means the car is using the brakes even when you are not! In a lot of systems, the TCS controllers will use the rear brakes for a “less intrusive” nanny. As a result, the rear pads get overused, leaving most folks with next-to-no rear pad material remaining at the end of a long track day. If you are comfortable and have the necessary seat time, we recommend disabling any nannies that utilize your braking system.